Collapse Strength Calculations

Timoshenko’s Formula, shown below, is commonly accepted to be the most accurate method available for estimating the collapse strength of steel pipe with diameter/thickness ratios common to those used in the construction of water wells.

Where: Pcr = Theoretical collapse strength of a perfectly round tube

Where: Pe = Collapse pressure with ellipticity (psi)

E = Young’s Modulus for Steel (3×107)

u = Poisson’s Ratio (0.3)

Do = Outside diameter of casing (inches)

t = Wall thickness (inches)

S = Yield strength (mild steel = 35,000 psi)

e = ellipticity, frequently assumed as 0.01

Shutter Screen, sometimes referred to as Louver Screen, actually has a greater collapse strength than casing of the same diameter and wall thickness due to the corrugating effect of the louvers. As a result, shutter screen’s collapse strength is up to 60% stronger than the pipe from which it was made.

Factors which determine the extent of increased strength include: the thickness/diameter ratio, slot size, slot length, and number of perforations. Modifications of the formula above can provide an estimate for the collapse strength of shutter screen.

Ps = Pe 1.20 Pf = Pe 1.35 Psf = Pe 1.60

Where: Pe = Collapse pressure with ellipticity (psi)

Ps = Collapse pressure of Standard shutter screen (psi)

Pf = Collapse pressure of Ful Flo shutter screen (psi)

Psf = Collapse pressure of Super Flo shutter screen (psi)

Collapse strength of continuous slot screen is dependent on diameter of the screen, size, shape, and material type of wire used in its manufacture, and the slot size. The following formula can be used to estimate the collapse strength of continuous slot screen.

Where: I = Moment of Inertia (in)4

![]()

Where: Pcs = Collapse pressure of continuous slot screen (psi)

E = Young’s Modulus for Steel (3×107)

w = Width of wire on external face (inches)

s = Slot width of screen (inches)

D = Mean diameter of the screen (inches)

h = Wire height (inches)

b = Width of minor base of wire (inches)

The following is the ASTM F 480 formula for determining the collapse strength of PVC pipe manufactured in accordance with said standards.

Where: Pc = Collapse pressure of PVC pipe (psi)

E = Young’s Modulus for PVC (4×105)

u = Poisson’s Ratio (0.33)

Do = Outside diameter of pipe (inches)

t = Wall thickness (inches)

Another formula used to determine the collapse strength of PVC is shown below. This formula, is more conservative than the ASTM formula. However, since most PVC materials are made to minimum allowable wall thickness rather than nominal sizes, it may provide a more accurate estimate of actual collapse strength.

Physical properties of PVC vary with temperature. The values obtained with these formulas are consistent with a temperature of 70°F. As the temperature rises, PVC working strength decreases by approximately 0.5 psi per degree Fahrenheit above 70°F. Obviously, much care must be taken during cementing operations or in other high temperature environments.

Weight Calculations

Weight of a blank casing, or pipe, can be found using the following formula.

Where: W = Weight of casing (lbs/ft)

Do = Outside diameter of casing (inches)

t = Wall thickness (inches)

m = Variable for casing material: Carbon Steel = 10.68;

Stainless Steel = 10.93; PVC = 2.04

Yield Strength Calculations

(ignoring buoyant forces) is determined by the following formula:

Where: Yp = Yield point of casing (lbs)

S = Yield strength (mild steel = 35,000 psi)

Do = Outside diameter of casing (inches)

t = Wall thickness (inches)

![]() = pi or 3.14159

= pi or 3.14159

For shutter type screen, this formula can be modified as shown here:

Yp = Yield point of casing (lbs) from above

l = Slot length perpendicular to the axis of the pipe (inches)

n = Number of circumferential slots

Do = Outside diameter of casing (inches)

t = Wall thickness (inches)

![]() = pi or 3.14159

= pi or 3.14159

For continuous slot screen we must determine the yield point for the screen and adjust for the joint connecting the screen body to the welding ring. This establishes the “safe hanging weight” of the screen. This is accomplished with the formula shown here:

Where: Ycs = Yield point of continuous slot screen (lbs)

S = Yield strength (mild steel = 35,000 psi)

r = Radius of rods or diameter/2 (inches)

n = Number of rods

j = Joint efficiency of connection between screen and weld

ring (generally assumed to be 0.70)

sf = Safety factor (assumed for this example at 0.5)

![]() = pi or 3.14159

= pi or 3.14159

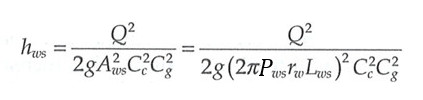

Area/Flow Calculations

hws = head loss across the well screen, (ft)

Aws = cross-sectional area of well screen, (ft2)

rw = well screen radius, (ft)

Pws = percentage of open surface of well screen with a length of Lws, (dimensionless)

g = gravitational acceleration, (32.17 ft/s2)

Lws = length of well screen, (ft)

Cc = contraction coefficient accounting for losses across the well screen, (dimensionless)

Cg = clogging factor accounting for the clogged portion of well screen, (dimensionless)

Calculation of percent of open area:

![]()

Where: Ap = Open Area (percent%)

A = Open Area (sq.inches)

Do = Average outside diameter of screen (inches)

Calculation of open area for shutter type screen:

![]()

Where: A = Open Area (sq.inches)

l = Slot length (inches)

o = Width of slot opening (inches)

n = Number of slots per foot

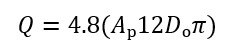

Calculation of the flow in gallons per minute per foot of screen:

Where: Q = Flow (gpm/ft of screen)

Ap = Open Area (percent%)

Do = Average outside diameter of screen (inches)

![]() = pi or 3.14159

= pi or 3.14159

Calculate Ap of shutter screen –

Calculation of open area for continuous slot screen:

![]()

Where: A = Open Area (sq.inches)

s = Slot size (inches)

w = Wire width (inches)

Do = Average outside diameter of screen (inches)

d = Diameter of rods (inches)

n = Number of rods

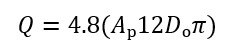

Calculation of the flow in gallons per minute per foot of screen:

Where: Q = Flow (gpm/ft of screen)

Ap = Open Area (percent%)

Do = Average outside diameter of screen (inches)

![]() = pi or 3.14159

= pi or 3.14159

Calculate Ap of continuous slot screen –