Water Well Accessories

Roscoe Moss Company manufactures custom accessories for specific water well designs.

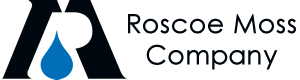

Centralizers are used to center the screen within the borehole. They are typically manufactured from 5/16 x 2 inch steel, 30 inches long, bent to provide the proper centering distance. This distance or bend is usually the theoretical borehole radius minus one inch. The guides are attached to the screen by welding. Three or four guides are placed equidistantly around the screen at specified intervals.

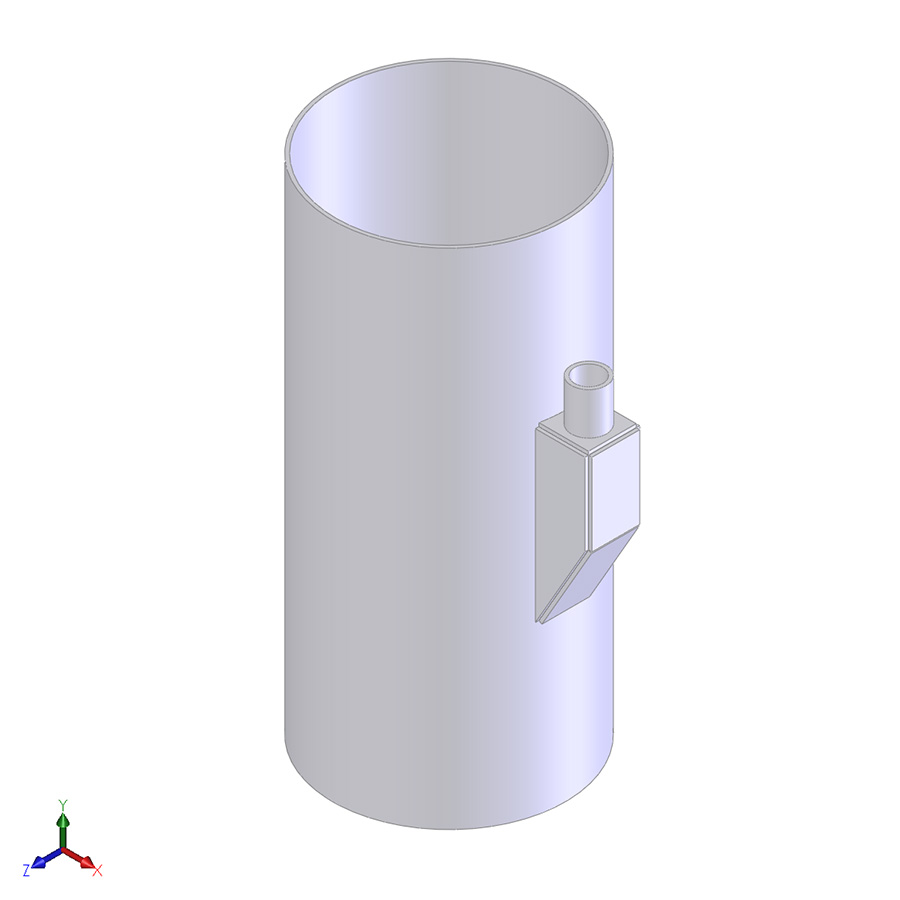

Roscoe Moss Company designs and manufactures specially entry ports to the casing. These entry ports are specific to the design of each well.

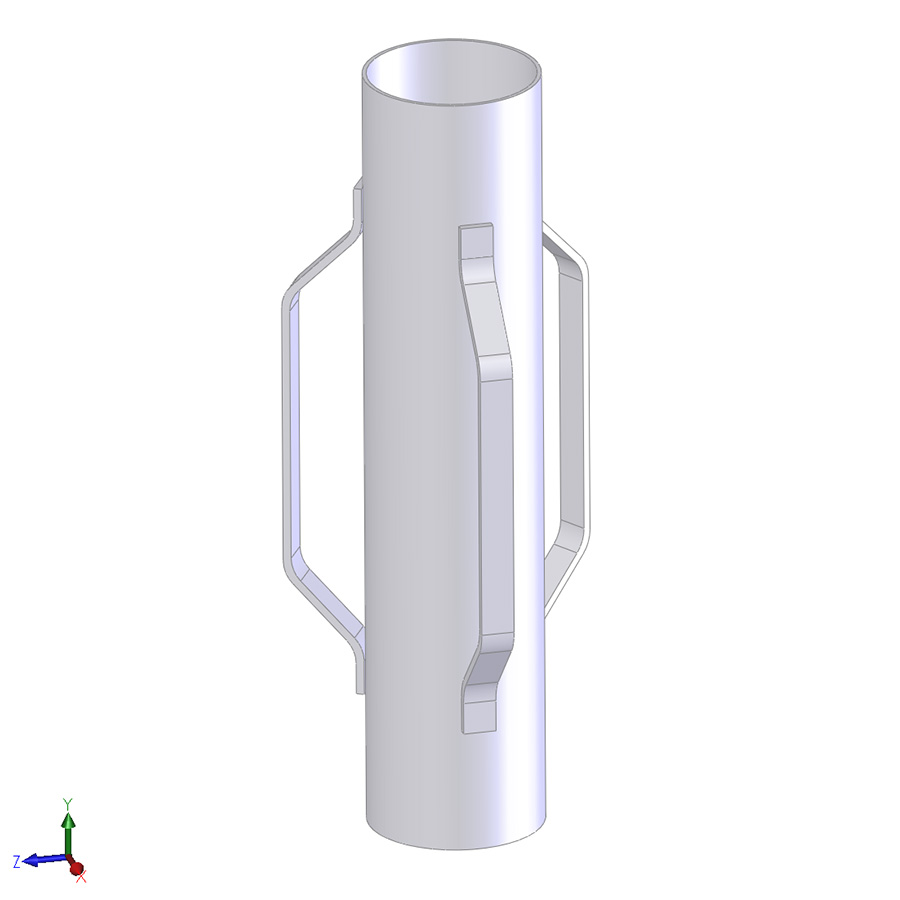

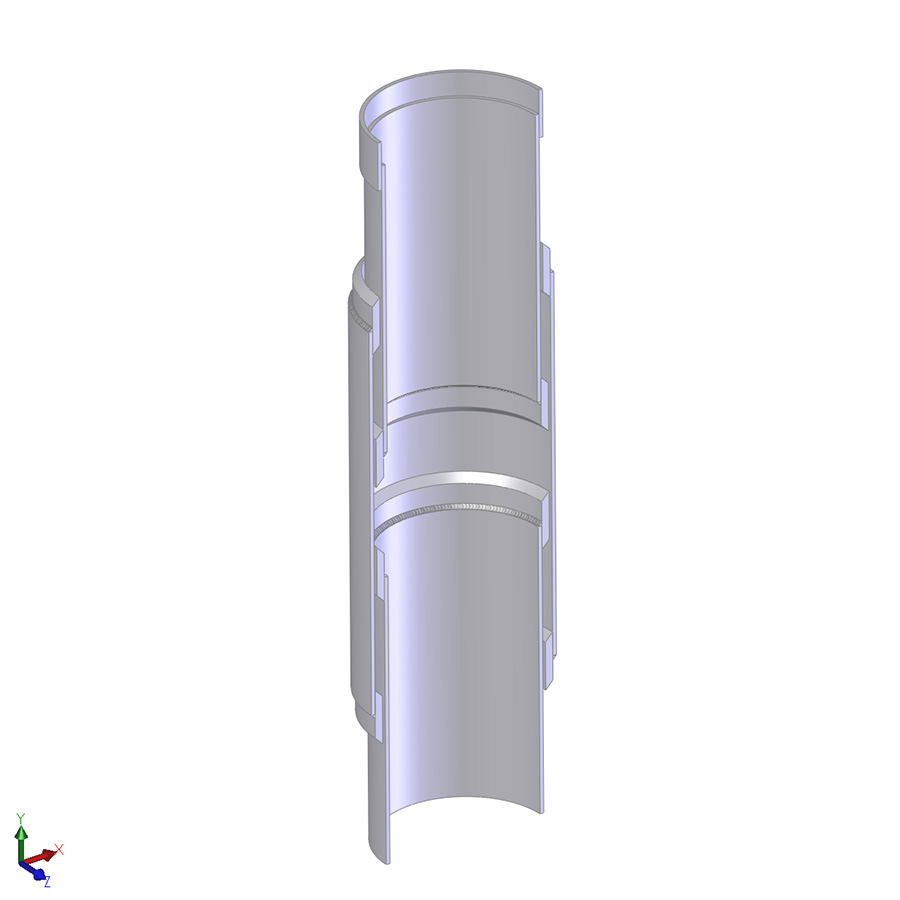

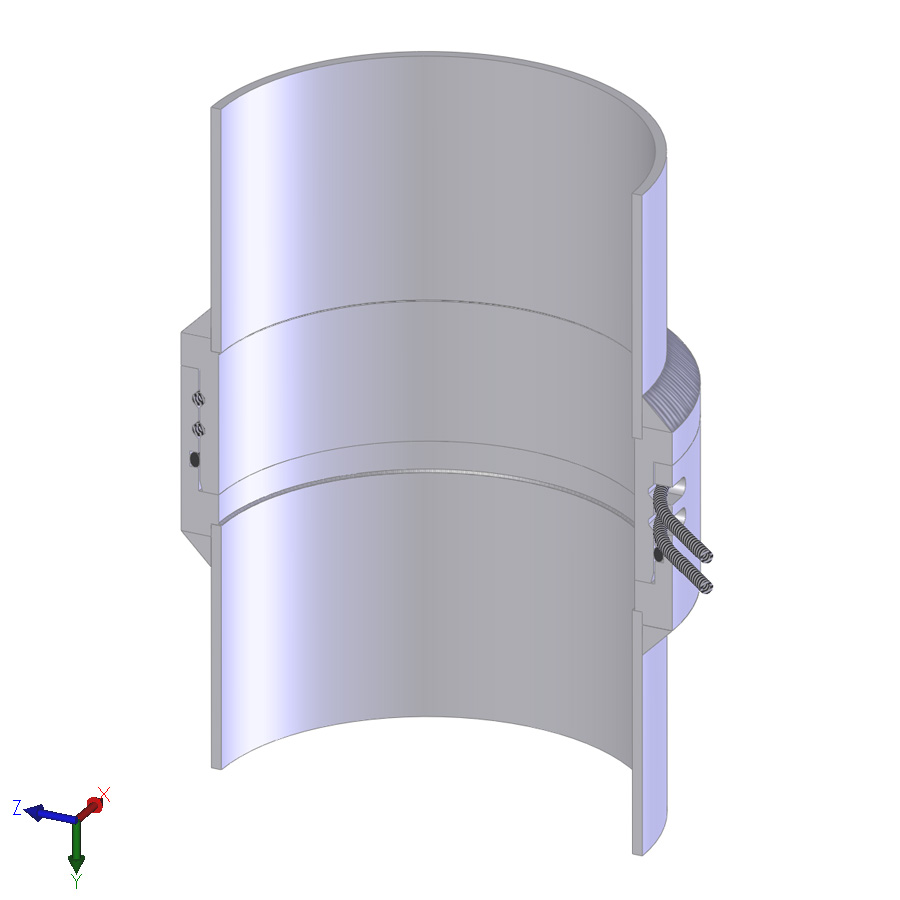

In many arid and semi-arid regions of the world, a cause of well failure is buckling of casing from ground subsidence due to over pumping. Use of compression sections can solve this problem.

Fabricated from 3 sections of casing, two of which are the same diameter and wall thickness as the casing. Joints are furnished with beveled steel rings. One ring is welded to the bottom of the upper section and one ring to the top of the lower section. Thus, the joints are free to telescope within the outer section which is equipped with rings at each end.

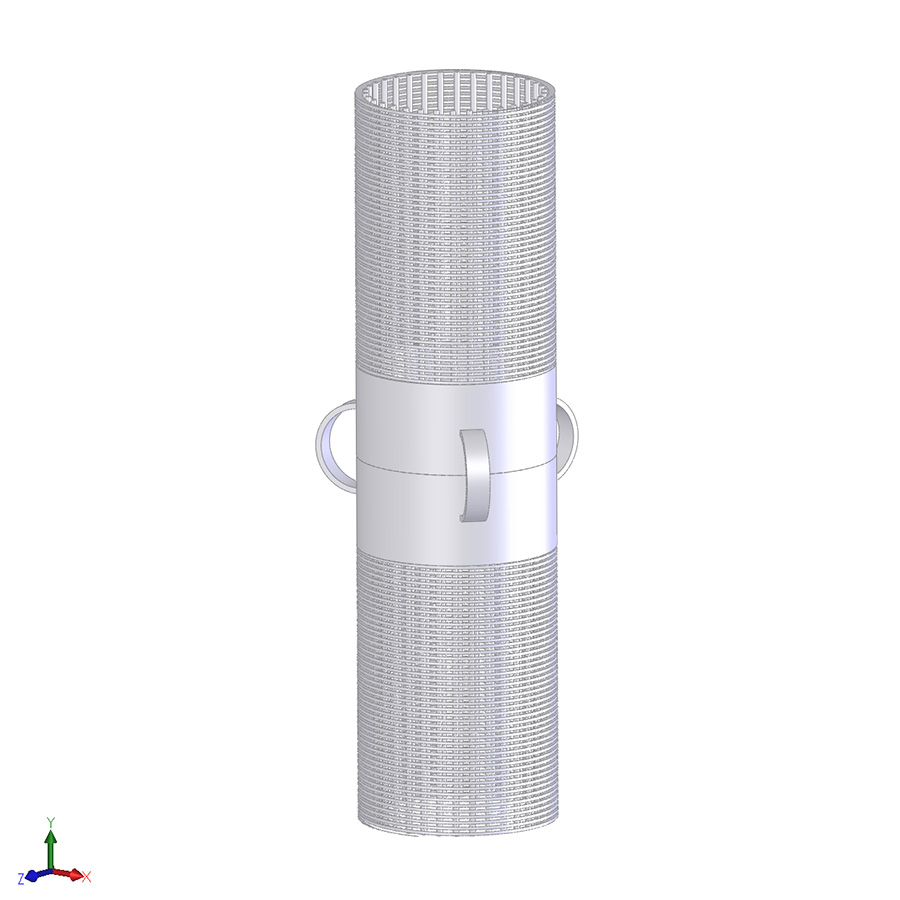

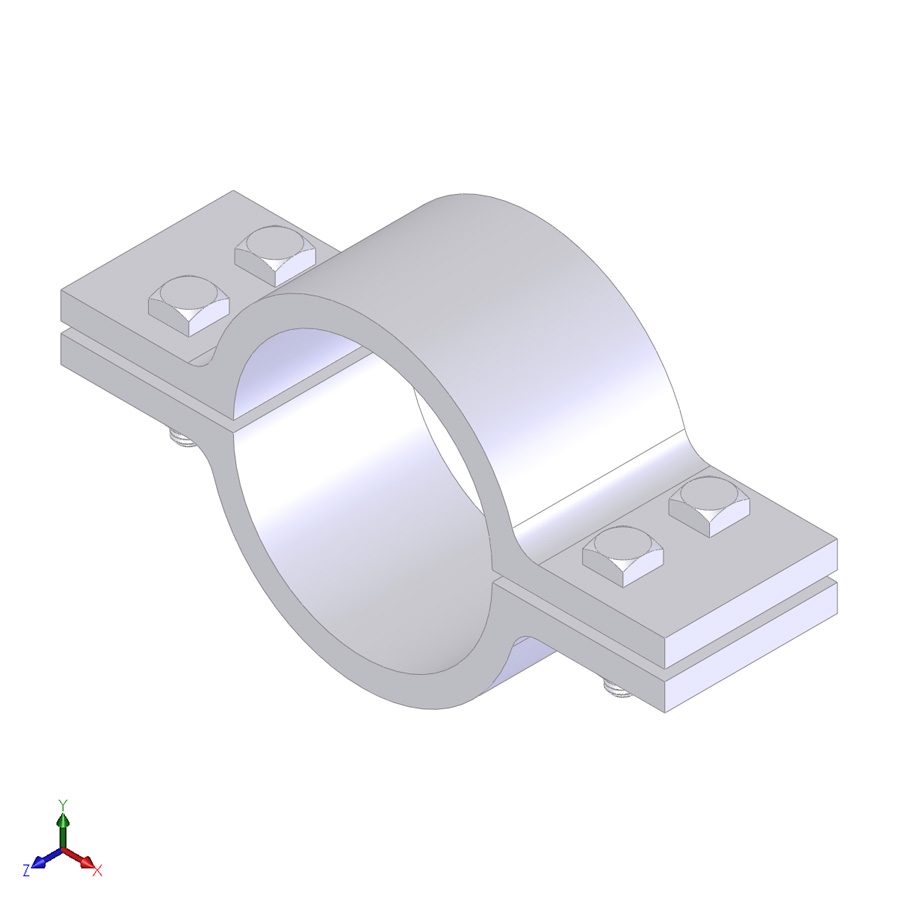

When casing and screen are installed in an open hole to be gravel packed, they should be suspended from the surface by a heavy duty clamp. This clamp may be supported at the ground surface by beams, or it may rest on or be notched into the surface protective casing. Surface protective casing, in turn, must be supported by beams or grouted in place. The purpose of suspending the casing and screen is to ensure the screen is held in tension during weld construction.

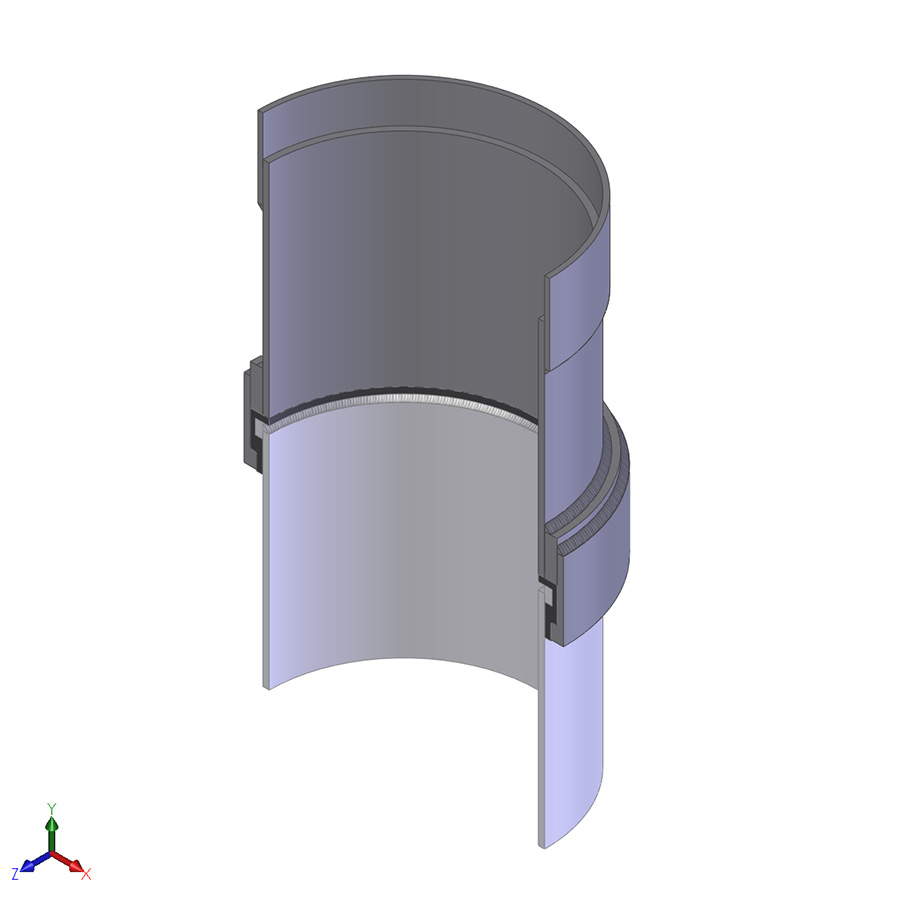

Electro-galvonic corrosion can occur between dissimilar metals (i.e. carbon steel to stainless steel). When joined together, an electronic reaction occurs between the two, corroding the less noble metal at an accelerated rate. This coupling is used to connect dissimilar metals, thereby mitigating the risk of electro-galvonic corrosion.

Double spline lock fittings were developed for fast installation of casing and screen with no field welding required. The double grooves and spline locking mechanism allow for quick connection and separation. This coupling is available in a variety of steel types and diameters.

These connectors are required when connecting a larger diameter casing to a smaller diameter casing.

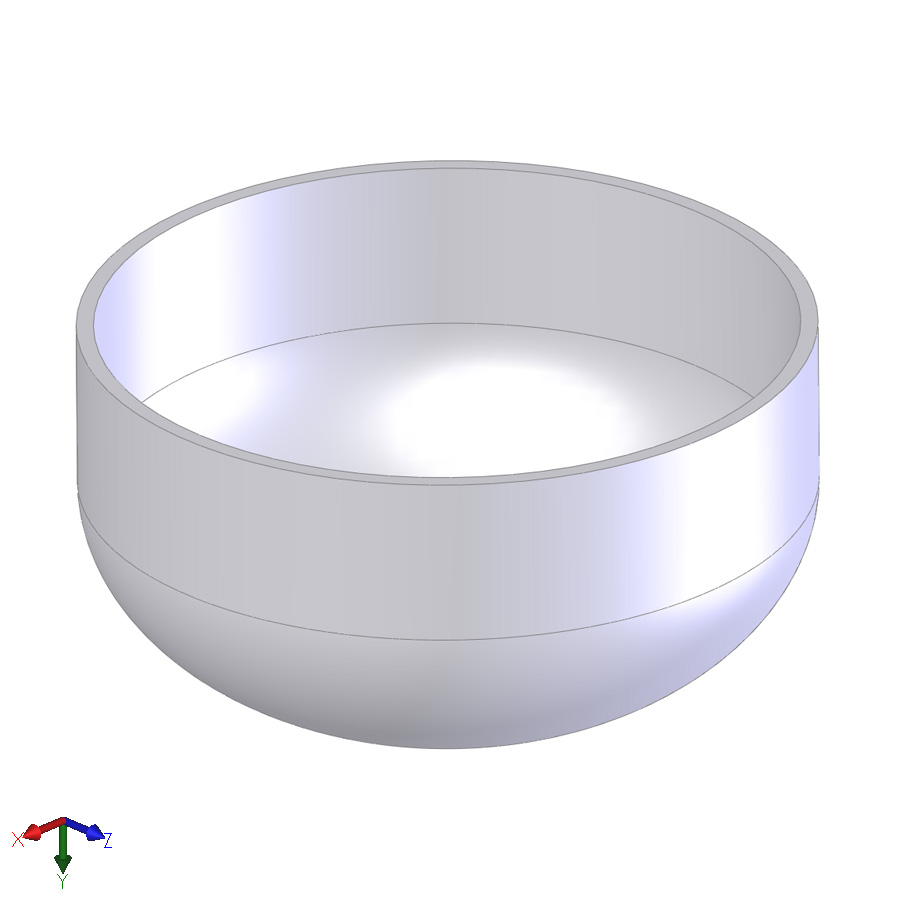

A bull nose or bottom plate should always be attached to the bottom of the casing or screen installed in gravel envelope wells. Semi-elliptical tank ends, readily available and inexpensive, provide a convenient fulfillment of this requirement.

Rossum Sand Tester Description

The Rossum Sand Tester is used to measure sand content of pumped water. This device is reliable, easy to use and relatively inexpensive. American Water Works Association Standard for Water Wells (AWWA A 100) Appendix E, Section E.4.6 “Measurement of Sand Content” states “Measurement of sand content may be accomplished by the installation of the Rossum centrifugal sand sampler…” This device has been manufactured by Roscoe Moss Company for over 40 years.

Measurement of sand content is often required of new water wells to determine if specified operating parameters have been achieved. However, well owners should include regularly scheduled sand tests in operation and maintenance programs.

Measurement of sand production on a regular basis may provide a timely indication of well problems. Should structural defects be detected early enough they may be repaired. If not abated, some conditions could lead to complete well failure resulting in decommissioning and replacement; a costly alternative that may have been avoided.

Please contact us for additional information regarding this product.

Directions for Using the Rossum Sand Tester

The Rossum Sand Tester is used to measure sand content of pumped water. These directions will allow the user to calculate this measurement in units represented as parts per million by volume.

The Rossum Sand Tester can be used to measure sand content in any water system. However, the water sample for sand determination must be carefully obtained. A sample collected from a horizontal pipe at low flow is unacceptable. The sample should be obtained from a vertical or horizontal pipe with highly turbulent flow. Samples taken immediately downstream from elbows, tees, and other fittings that create turbulence are generally satisfactory.

Procedure

- Install the Rossum Sand Tester according to instructions provided. The inlet should be located on the horizontal centerline of the discharge pipe and be as close to the discharge head or other turbulent flow area as possible.

- Completely open the inlet valve to the tester. Adjust the outlet valve to 1/2 gpm (this will fill a quart container in 30 seconds or a gallon container in 2 minutes).

- Close the inlet valve, remove, clean, and replace the Pyrex tube.

- When ready to start the test, completely open the inlet valve and note the time.

- Periodically record the accumulated sand and time. It is important to note that the most common mistake made when doing the final calculation is dividing total accumulation of sand by total time. This provides only the average sand content. Instead, it is necessary to divide the incremental sand increase by the incremental time increase. This will provide the sand production at a specific time ie. sand production 15 minutes after the start of the test.

- Check the flow rate through the tester during each run. If the flow rate is not 1/2 gpm, repeat the test.

- Record the pump discharge rate (gpm) during each sand test and note whether any surging was done prior to the test.

Rossum Sand Tester Calculations

Calculation:

The sand content is determined from the following formula:

| incremental accumulation (ml) / incremental time (mins) | ||

| ml sand per ml water | = |

|

| .5 gpm x 231 in3/gal x 16.387 ml/in3 |

Therefore:

Sand content (ppm) = ml sand per ml water x 1,000,000

Simplified:

| incremental sand accumulation (ml) x 528.3 | ||

| sand content (ppm) | = |

|

| incremental time interval (mins) |

Rossum Sand Tester Order Form

To order the Rossum Sand Tester please call us at 1-323-263-4111 or download our order form, complete and fax to 1-323-263-4497. A representative will contact you upon receipt of your order.