Roscoe Moss Company manufactures water well casing and screen in a variety of corrosion resistant materials. Factors such as water quality, strength requirements, and expected well life all play an important role in determining what steel type is best for each specific job.

Duplex Stainless Steel Types 2101, 2205, 2507

Duplex stainless steel is the appropriate material for specific environments where corrosion is extreme. Typical applications include brackish water, desalination, and brine injection. Duplex stainless steel offers superior corrosion resistance combined with high strength.

Stainless Steel Types 304/304L and 316/316L

Stainless steel is used for wells where corrosive elements limit the effective life of carbon, copper-bearing and HSLA steels. Stainless steel is particularly resistant to detrimental effects of hydrogen sulfide, carbon dioxide and saline water. Removal of incrustation by acidizing, a method not recommended for some other steels, may be accomplished in stainless steel screens.

High-Strength Low-Alloy (HSLA) Steel

Corrosion-resistant, high-strength low-alloy steel casing and screen is designed and produced for use in water wells when corrosion resistance, strength and durability are important requirements. Stronger than mild or copper-bearing steel, HSLA casing and screen is an excellent choice for deep, large-diameter wells. Although more corrosion resistant than mild or copper-bearing steel, in wells where severe corrosive elements are present, an analysis must be made before selecting this material over stainless steel.

Copper-Bearing Steel

Used for wells where resistance to corrosion is an important requirement. Although not as corrosion-resistant as HSLA or stainless steel, copper-bearing casing and screen last significantly longer than mild steel products.

Mild Steel

Also referred to as Low Carbon Steel, this is used for wells when short-term economic considerations are a priority.

| Steel Type | Manufacturing Specification | Yield Strength (psi) | Tensile Strength (psi) | PRE* | |

|---|---|---|---|---|---|

| Duplex Stainless Steels | 2507 | ASTM 928 | 80,000 | 110,000 | 42 |

| 2205 | ASTM 928 | 65,000 | 95,000 | 35 | |

| 2101 | ASTM 928 | 65,000 | 94,000 | 26 | |

| Austenitic Stainless Steels | 316L | ASTM 778 | 30,000 | 75,000 | 24 |

| 304L | ASTM 778 | 30,000 | 75,000 | 18 | |

| Carbon Steels | High Strength Low Alloy (A606 Type 4) | ASTM 139 | 50,000 | 70,000 | N/A |

| Copper Bearing | ASTM 139 B | 35,000 | 60,000 | N/A | |

| Mild Steel | ASTM 139 B | 35,000 | 60,000 | N/A |

*PRE = %Cr + 3.3x%Mo + 16x%N

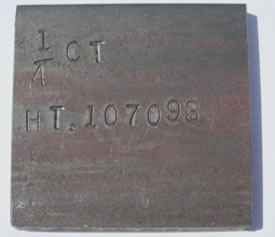

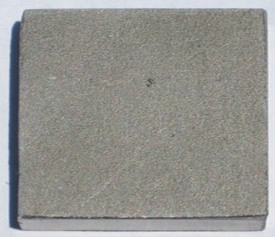

Physical Properties

| Mild Steel | Copper Bearing | High Strength Low Alloy | SST 304L | |

|---|---|---|---|---|

| Image Of Finished Product |  |

|

|

|

| Corrosion Resistance | x | 4x | 9x | 244x |

| Physical Properties | Iron > 98% | Minimum 0.2% Cu | Min. Amounts of Cu, Ni, Cr | 18-20% Cr 8-13% Ni |

| Yield Strength | 35,000 lbs/in2 | 35,000 lbs/in2 | 50,000 lbs/in2 | 30,000 lbs/in2 |